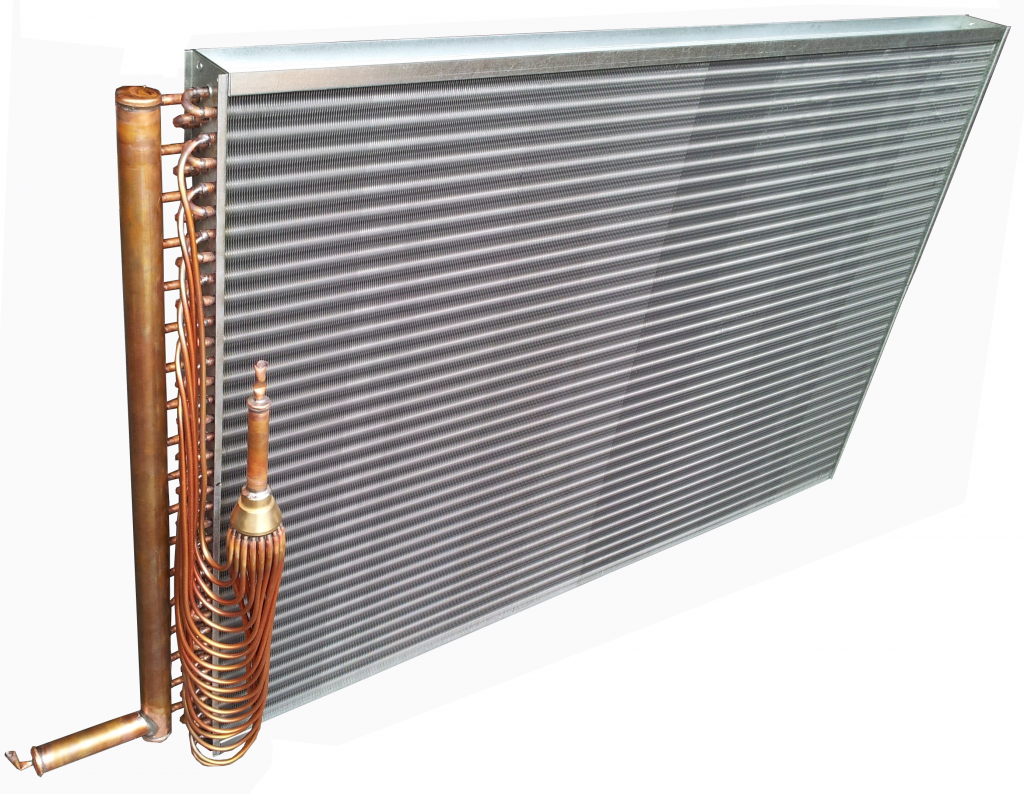

Thermal-Matic Coil has developed the capability to manufacture coils with a wide range of materials including copper, aluminium, E.G., galvanized steel, and stainless steel 304/316. A few numbers of coil coating are also available to help match a corrosion and wettability solution to your environment condition. Thermal-Matic has capability to efficiently manufacture a wide range of coil sizes and dimensions. Coil body can be manufactured with tubing diameters ranging from 3/8″ to 5/8″ with length from 5″ to 180″.

Thermal-Matic main products include air cooled condenser, unit cooler and tailor made or replacement fin coil. Our air cooled condenser is commonly used for air condition room, server room and cold room which include ante room, chiller room, freezer room, etc. Where else our unit cooler is usually use for cold room and air condition room.

Thermal-Matic also fabricate tailor made coil from new design, rectify existing coil & redesign, and replacement coil.

Thermal-Matic coils are all QC check for in each department and 100% leak tested before delivery. We are tight on our quality requirement and ensure customer gets what we have promised.

Features:

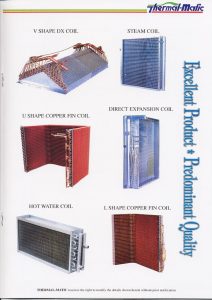

Product Range:

DX / Evaporator Coil (Vertical or V-shape)

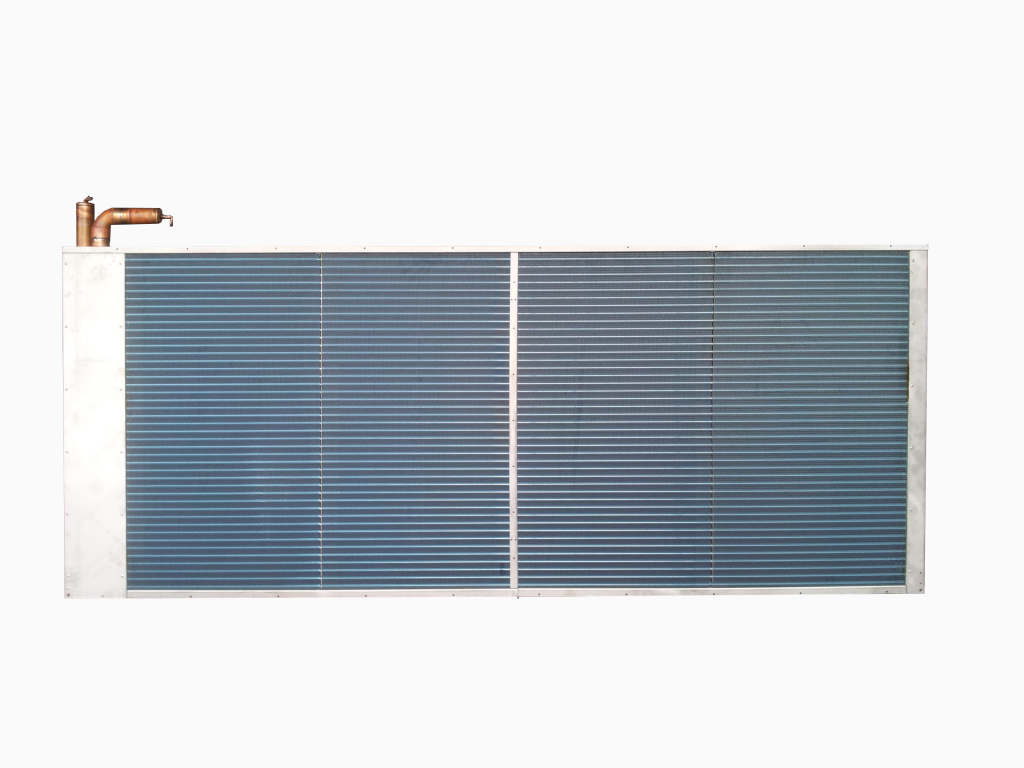

Condenser Coil (Vertical, Horizaontal, L, V, or U shape

Chilled Water Coil

Hot Water Coil

Steam Coil

Bare Coil

Fins:

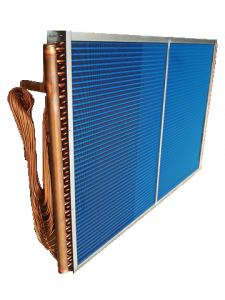

Fins are fabricated from either Aluminium or Copper with extruded collars to maximize heat transfer and ensure accurate fin spacing. Fin surfaces are available in corrugated, sine wave or enhanced with enhanced with edges that are straight or rippled. Special chemical coating for marine enhance application is available upon request. Spacing available from 3 FPI to 20 FPI (Fin Per Inch).

Tubes:

Seamless drawn copper tubes are available in 3/8″Ø, 1/2″Ø & 5/8″Ø. Grooved tubes are available on request.

Casing:

Standard casing with galvanized steel. For better resistance to prevent corrosive is by using Stainless Steel – 304 (2B) or 316L (2B) on request.

Header:

Header is fabricated from copper, galvanized steel and schedule 40 (Steam Pipe).

Testing:

All coils are 100% leak tested under water using high pressure dry air 350-400 PSIG.