DX (Direct expansion) coil is one of the evaporator coils uses refrigerant as a cooling medium in a close loop system for cooling. DX coil directly cool the supply air to an occupied space.

Expansion refers to the treatment of the refrigerant (expansion valve is used to reduces its pressure and temperature) before entering the evaporator. There are 2 general type of DX systems:

1) Package system – equipped with all the components in a unit, and

2) Split system – the whole system split into indoor unit and outdoor unit.

Features

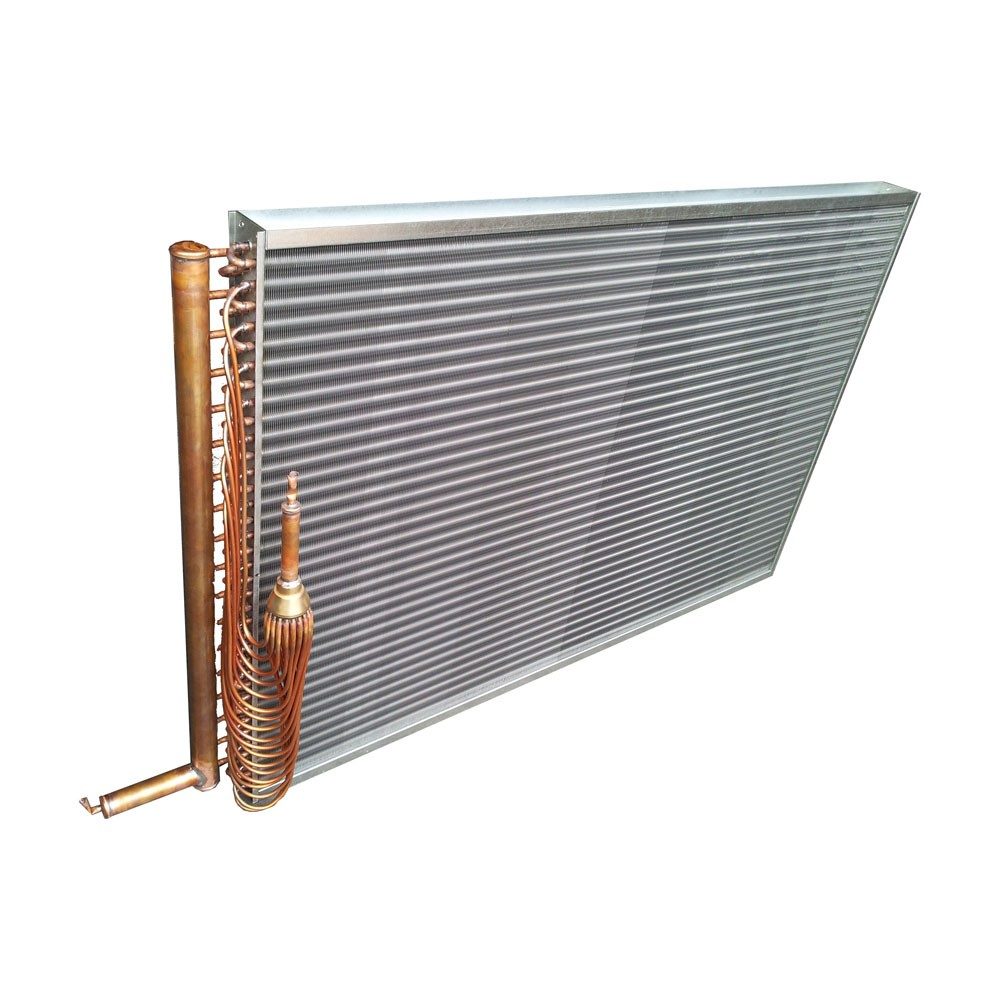

Fins

Fins are fabricated from either Aluminium or Copper with extruded collars to maximize heat transfer and ensure accurate fin spacing. Fin surfaces are available in corrugated, sine wave or enhanced with enhanced with edges that are straight or rippled. Special chemical coating for marine enhance application is available upon request. Spacing available from 3 FPI to 20 FPI (Fin Per Inch).

Tubes

Seamless drawn copper tubes are available in 3/8″Ø, 1/2″Ø & 5/8″Ø. Grooved tubes are available on request.

Casing

Standard casing with galvanized steel. For better resistance to prevent corrosive is by using Stainless Steel – 304 (2B) or 316L (2B) on request.

Header

Header is fabricated from copper, galvanized steel and schedule 40 (Steam Pipe).

Testing

All coils are 100% leak tested under water using high pressure dry air 350-400 PSIG.